All of us Marzocchi Fork Users come to the point in life where we have to decide about the material of our steerer’s : Aluminium or CroMo (Chrome Molybdenum)!?

In most cases it is about weight and the difference can be around 200 – 300 gr, depends on the length, diameter and type.

Over the years I reveived a lot of requests about aluminium steerer for the older Marzocchi Forks – using in pressed-in or boltened Steerer Fork Crowns – in most cases I was able to help out with older used ones from my steerer boxes.

But have you ever compared old style Aluminium Steerer with current ones? You will wonder.

Look at the photo’s. You will realize the newer one looks different, they have a somehow ‘rough’ surface and are very shiny.

Q: Why do the Steerer look so different?

A: Easy : They have not been lathed like the older ones, but extruded. This is a modern procedure in modern material mass production. It also have sand lasted and for better looking they have some electro chemical quick surface finish. All in all this makes them cheaper in production & profit grows up, but it is not all good.

The one making by ‘good old Style’ has been lathed.

Q: What are the main important advantages of the Old Style ones?

A: There are Several Reasons :

- homogenous material, means …

- better strength (!)

- defined geometry (think about your headset placed on the steerer)

- better surface (*)

- better (defined!) tolerances! (*)

- defined flat bottom part (*)

(*) main important : this is needed for Steerer PRESSED-IN into Fork Crowns!!

Easy to understand, eh?!!

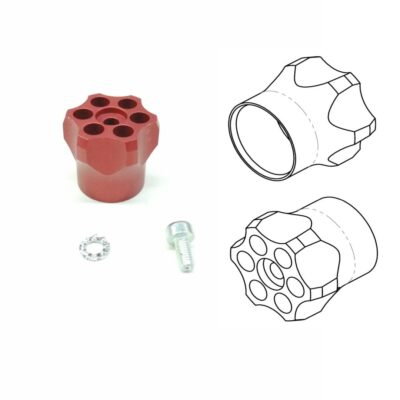

So that’s it, I will try to create a batch of Steerer’s in the ‘Old Style’ from the 90’s using some optimisations :

- optimized tolerances for pressing procedures

- optimized conical design to optimize the transfer of forces (above the headset)

- optimized surface : anodized for protection & better handling

- power force optimized wall thinkness (a little more wall thickness)

- material optimized

- and surely this can be used for boltened Marzocchi Fork Crowns also!

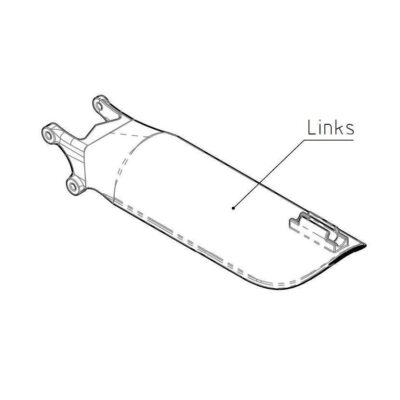

B. ‘Old Style’ Steerer – lathed

- Low defined bottom edge

- Defined geometry for bottom Headsets Bottom Bearing Ring

- Sand blasted Surface, cheap electro-chemical treatment

- Lathed surface

- Defined geometry from bottom Headsets Bottom Bearing Ring to conical part

- Defined geometry from bottom pressing part -> bottom Headsets Bottom Bearing Ring

- Defined ‘sharp’ geometry