Welcome to my Blog about older Marzocchi Forks from the 90's!

The blog of a real Marzocchi maniac. Rebuilds. Spares. Seals. Reproductions!! Services.

Brake Cable Clamps / V-Brake Replacements (2003-2011)

This are some small bits you need to have your Marzocchi fork full assembled & ready to go with Disc Brakes. It's so easy to loose them. And now we have all 5 out of 5 done and ready!!✨🎈🙏 I did all this parts by 3D Printing using SLA process with black resin as...

Fox Alps 4/5 (R) Shocks => NEW Retro Parts Project!!🖐🧩⚡✨🙏🤙

As I have several Fox Alps shocks (check blogs's title picture) and need a backup shock for my daily Verlicchi/Sintesi Bromont Bike I'm going to do my own very best Spare Parts Kits for Fox Alps Shocks now.🙏🤙 If you read here you know about Fox Alps v4 & v5 and...

New CNC Marzocchi MONSTER Top Caps 1999-2002 & 2003-2006!

As promised I have created some batch of very nice new MONSTER's TopCaps in 3 colours created in High Quality CNC production. Discount starts with >=2 pcs. 2003-2006 MONSTER Top Cap’s include : Top Cap (choose out of 3 colours) Top Cap’s O-Ring Deflating Screw...

Demo Design-Project SHIVER DC Top Caps with custom Splash-Design!!✨⚡👍🖐👀

Just a little Demo Project in Cooperation with Kai Herm 👊🧬 to show such new SHIVER DC Top Caps in Splash Design. You probably know a lot of the different SHIVER DC Models have Design/Stickers/Parts in black and red ... All of this Splash Designs are absolute unique!!😱...

Marzocchi SHIVER DC blue Top Caps & Axle Screws – custom anodized!!

All possible, re-anodizing thankfully done in professional way by Kai Herm !! Thanks!! New SHIVER Top Caps & Axle Screws have been done by me this year and are in stock in 4 colours silver, black, red, blue. You can see they are from top Quality. I changed the...

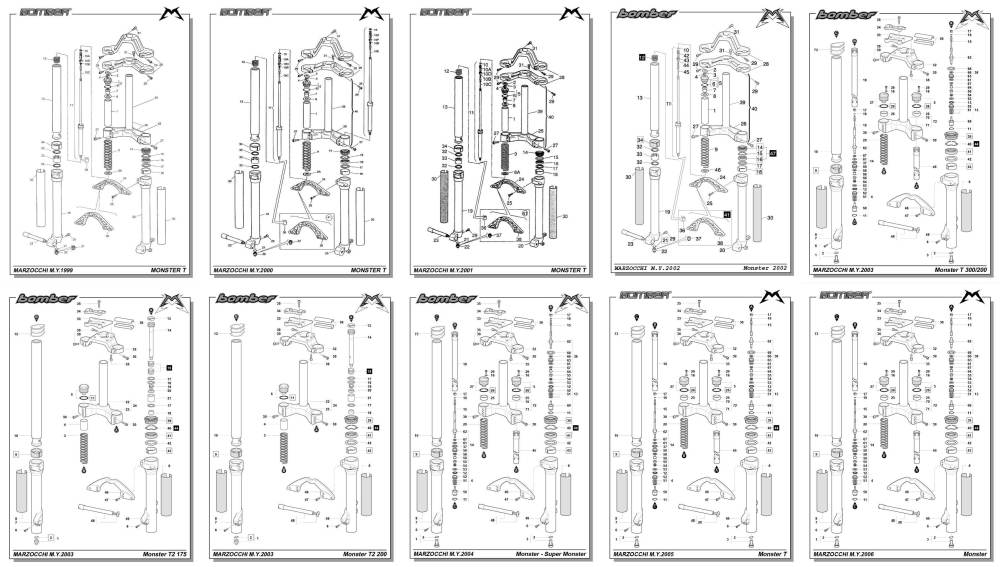

Marzocchi MONSTER’s Exploded Drawing Overview to your Service✨👊😱🤙

I needed some pictures to compare MONSTER versions Top Caps as I'm in a production cycle now, may be some others can use it .... HRES version on request!