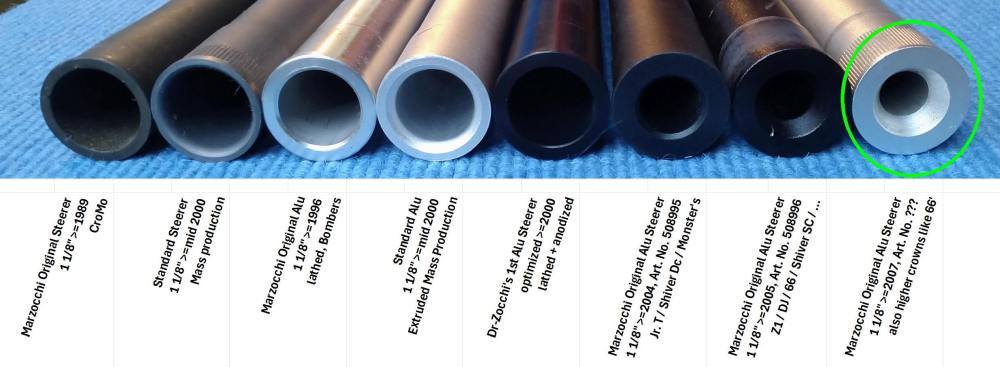

I like to show you, how Steerers have been developed in the last ~35 years. Marzocchi starting in 1989 made rock solid HQ CroMo steerers in 3 sizes (1″, 1 1/8″, 1 1/4″) for all the XC forks (you know : StarFork, … XC500, XC600 etc.).

And when evolution of suspension forks continuoued, forks got more weight and users demand was about some weight tuning in steerers.

You know when bullet-proof Bomber’s appeared on the market 1997+ and following Marzocchi developed in weight optimizing modells like BAM, Alloy and others.

Over the year Marzocchi continoued developing different geometries – keep in mind it was a company of developers, not such wtf-buy-it-only-and-don’t-care-get+make_more_money-companies we have today.

The 3D geometry of a steerer needs to handle various level and vectors of forces. In the beginning this have resulted in ‘simple’ straight tubes, the later it became some optimized conical design – btw. same happened with Marzocchi stanchions!

Aluminium 7075 T6 is a fascinating material – heavy used in Aero Industry, Rocket Science and more. It’s high quality variants like ‘T6’ are best choice to repro such steerers.

I’m doing now length up to 280mm, that’s just to save some production costs. The original have been >=300mm.

The marked green one but black is the one which is in production now.👀🖐

FYI : There is one strong Marzocchi CroMO Steerer missing in the picture, I show you somewhen later. It is a variant with another additional inner CroMo core which is pressed into the steerer to avoid dynamic distorsions which results in cracking in all other modern brands, but not for the time Marzocchi rulez the world🙏🤗🥇🤣🤣🤣.